CANDOCK FLOATING DOCK SYSTEMS

The CanDock floating dock system is a modern solution for those seeking a durable, versatile, and user-friendly floating system for their waterfront property. It offers a unique combination of practicality and aesthetic appeal, making it an ideal choice for both private and commercial use. Understanding the specifics of the CanDock system can help potential users make an informed decision about their docking needs.

HOW CANDOCK WORKS

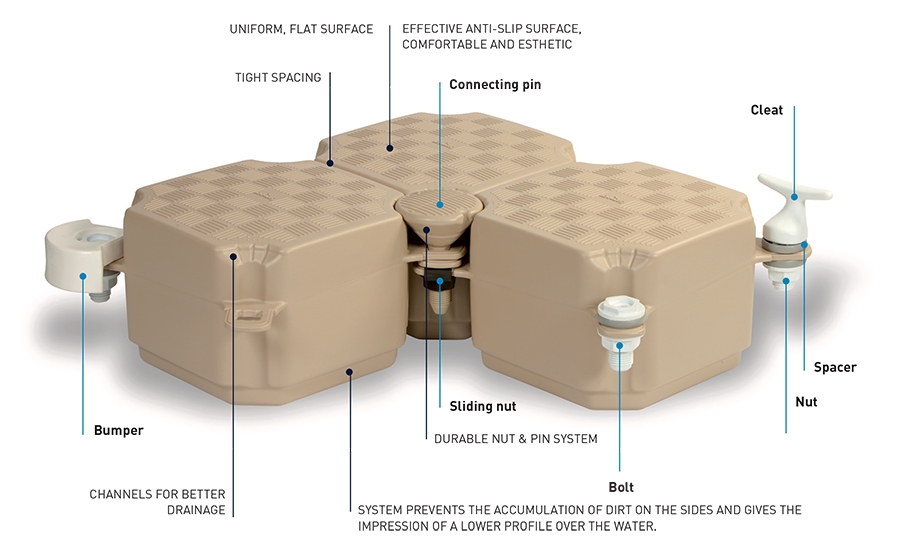

The CanDock floating dock system is composed of high-density polyethylene cubes that are used to create a stable and durable platform on the water. These modular cubes can be assembled in various configurations, allowing for customization to fit specific needs and waterfront environments.

- Material and Design: The cubes are made from high-quality, environmentally-friendly polyethylene. They are UV resistant, which prevents degradation from sunlight exposure and the cubes are remarkably resistant to impact, climate change, and the adverse effects of water. The design also incorporates a uniform, flat surface with anti-skid patterns, ensuring safety and stability for users.

- Unlimited Number of Configurations: One of the primary advantages of the CanDock system is its modularity and the unlimited number of configurations. The individual cubes can be connected in countless configurations, making it adaptable to different waterfronts and user requirements. This flexibility is ideal for those who may want to expand or change their dock layout over time.

- Ease of Installation and Maintenance: The installation of CanDock systems is straightforward: tightly interconnected blocks are secured using specialized mounting screws. Each component is lightweight and effortless to maneuver and does not require specialized tools or heavy machinery. Additionally, the system is low-maintenance, resistant to corrosion, and does not require painting or staining.

- Buoyancy and Stability: The cubes are designed to provide excellent buoyancy and stability. They adapt to the changing water levels, making them ideal for areas with fluctuating water conditions. This buoyancy also ensures that the dock remains stable and secure in various weather conditions. Each cube provides a 150 lb floating capacity.

CanDock's innovative design comprises numerous compact floating modules linked to form expansive configurations. In contrast, alternative systems employ larger sections that join to create extensive layouts. The choice to utilize a multitude of smaller floats over a single large float for a dock presents multiple advantages:

- Stability - Multiple points of buoyancy can provide a more stable platform. The weight distribution is more even, reducing the risk of tipping or sinking if one section becomes overloaded.

- Durability - If one float is damaged, it can be replaced without replacing a $1500 to $2500 section. This modular approach can extend the overall life of the dock and make maintenance more manageable and cost-effective.

- Shock Absorption - The distributed nature of multiple small floats can offer better shock absorption from waves and boat wakes, leading to a smoother experience for those using the dock.

- Load Distribution - Smaller floats distribute the dock's load over a larger area, which can reduce the stress on any one point of the dock structure, enhancing its longevity and safety.

- Resilience - In the event of a puncture or leak, the redundancy of having multiple floats means the dock will likely remain afloat and usable until repairs can be made. In contrast, a single large float could render the dock unusable if it were to sustain similar damage.

The CanDock system is thoughtfully engineered to prioritize environmental protection and sustainability. Constructed from materials that are not only non-toxic but also fully recyclable, the system reflects a commitment to reducing its ecological footprint. This eco-conscious approach extends to its design, which ensures adequate water flow beneath the dock. Such a feature is crucial for mitigating the dock's impact on the aquatic ecosystem, helping to preserve the natural habitat for marine life. Additionally, this continuous water flow plays a vital role in upholding the purity and quality of the water and maintaining the health of our waterways for future generations.

APPLICATIONS AND USES

The versatility of the CanDock system makes it suitable for a wide range of applications. The system represents a blend of innovation, durability, and versatility. Its modular design allows for extensive customization, making it suitable for a wide range of applications, from private residential docks to large commercial marinas. The ease of installation and low maintenance requirements add to its appeal, making it an efficient and cost-effective solution. Its environmentally friendly design ensures a minimal impact on the aquatic ecosystem.

- Residential Use: For homeowners, the CanDock system offers an aesthetically pleasing and functional solution. It can be used for docking boats, jet skis, and other watercraft or simply as a floating platform for recreational activities.

- Commercial and Marina Use: The strength and adaptability of the system make it suitable for commercial applications, including public marinas, boat clubs, and rental operations. The system can be configured to accommodate multiple watercraft of different sizes.

- Specialized Applications: Beyond typical docking uses, the CanDock system can be adapted for specialized applications such as floating walkways, fish farms, and temporary or permanent event platforms.

CANDOCK ANCHORING

Correctly anchoring your floating dock is crucial for maintaining its stability and position. Without proper anchoring, docks can drift due to currents, wind, or boat wakes, leading to potential damage to the dock itself, boats moored to it, or nearby structures. Below we discuss the different options for anchoring CanDock Drive On Platforms.

Post & Piling - Using posts or pilings for anchoring a floating dock is a time-tested and dependable method. Selecting the appropriate size of the post or pile is crucial and depends on the location of the installation. For posts with a diameter of up to 4 inches, anchoring Cubes are an effective solution. There are specially designed brackets for bigger pilings that can be easily attached to the CanDock, ensuring a secure and stable anchoring system.

Struts & Stiffarms - This anchoring method uses aluminum extrusions and brackets, which are affixed both to shore and to the dock. This setup establishes a fixed distance from the shore, effectively securing the dock in position. To enhance stability and maintain the structure's integrity, cables are typically arranged in an X pattern between the struts or arms. This technique is particularly suitable for docks situated near the shore, especially in situations where using posts or pilings is impractical due to deep waters or soft lakebeds.

Dead Weight - This method involves using heavy weights, typically made of concrete, which are placed on the lake or seabed. These weights are connected to the dock through chains, cables and/or ropes. The gravitational pull ensures the dock remains anchored in its designated spot, countering water movements and wind. Brackets that attach to the CanDock without damaging the cubes are available and provide the necessary connection point and strength needed to hold the dock in place.

H-Beam Sliders - This anchoring method employs a vertically mounted I-Beam and a specialized bracket. The bracket, fitted to the I-Beam, features rollers that enable it to move up and down without any resistance. The other part of the bracket is secured to the dock, allowing it to easily adjust to variations in waves, tides, or water levels. However, this configuration ensures the dock remains firmly in its designated position without drifting. This system is particularly effective in locations where water levels fluctuate regularly, providing a stable and adaptable anchoring solution.

Direct Connect - A direct connection is suitable when linking to another floating system or in areas with stable water levels. However, it's rare to find locations where water levels remain constant, so we generally advise using direct connections only with other floating structures. This approach ensures synchronized movement, preventing stress or binding. Conversely, directly attaching a floating dock to a fixed structure can lead to issues, even with minor water level changes. Therefore, this method is best reserved for scenarios where both connected systems can move harmoniously with the water's ups and downs.

WHAT ARE THE NEXT STEPS?

If you would like to get an estimate for a CanDock system and need some assistance, below is a list of information that we need in order to provide an accurate estimate. Take a look, and feel free to reach out with any questions or concerns.

- Project Requirements: What is the intended use for the floating dock?

- Preferred Design and Dimensions: What size and shape do you want for the modular floating dock system?

- Vessel Specifications: If docking is needed, what are the details (make, model, year, engine type, and other specifications) of the vessel(s) that will be docked on the Candock modular floating dock system?

- Additional Vessel Details: If applicable, provide the specifications (make, model, year, engine layout, and other relevant information) for any other boats that will be moored at the Candock modular floating dock system.

- Environmental Details: Please provide a description of the surroundings, including images, videos, geographical coordinates, or the address.

- Shoreline Type: Describe the nature of the shoreline where the dock will be installed.

- Water Body Characteristics: What is the nature of the lake, river, or seabed?

- Access Requirements: Is an aluminum ramp needed for access to the dock from the shore (Gangway)?

- Wind and Wave Protection: Is the chosen location sheltered from wind and waves? Please provide details and supporting data.

- Water Level Variability: Is the site subject to changes in water levels, whether tidal, seasonal, or other? Provide specifics and measurements.

- Depth Measurements: What are the water depths at low tide at the start, middle, and end points of the proposed dock location?

- Delivery / Shipping Address: We need to know where you need it.

ADDITIONAL INFORMATION

- Delivery options include local delivery, shipping via common carrier freight or local pickup.

- Upon dispatch by the freight carrier, tracking details will be provided by email.